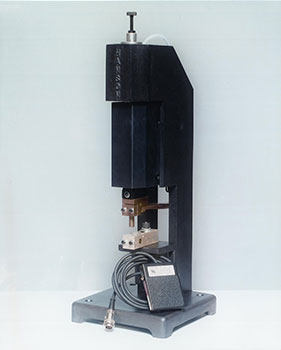

BENCH TYPE WELDING & SOLDERING HEAD

HS-2/HS-2-2D

The Hanson HS-2 bench top welding and soldering head is a precision unit that allows you to design your own welding or soldering machine. It can be matched up with power supplies from 0.5-20 KVA A.C. and with 5-500 watt/second D.C. supplies. This unit can be coupled with existing power supplies or Hanson can provide you with a choice of welding transformers and controls.

What is Precision Welding?

Precision welding is the process by which welds are applied to a work piece in an extremely precise and controlled fashion. Dimensional tolerances for the welded location commonly range less than ±0.2 mm (0.008 inch) for both the depth of the weld and position of the weld line. Precision welding is often used for very small parts, parts with tight dimensional tolerances, and parts requiring a barely visible line weld. Hanson's precision welding machines provide computer control of the work piece and the welding heat source for high quality precision that can't be duplicated without automation.

Hanson Welding is a unique purveyor of precision welding machines including machines that offer electron beam welding (EBW), laser beam welding (LBW), and hermetic laser sealing. For 30 years we have been helping customers fulfil their precision welding needs with our talented engineering staff as well as our wide assortment of precision resistance welding equipment.

What is Resistance Welding?

Resistance Welding is a welding technique in which the parts to be joined are held together under pressure and heat is produced by passing a current through the contact resistance formed between the two surfaces. The primary advantage of resistance welding is that no other materials are needed to create the bond, making this process extremely cost effective.

While there are many different types of resistance welding (e.g. spot and seam, projection, etc...), they mainly differ by the types and shapes of weld electrodes that are used to apply the pressure and conduct the current. The electrodes, are most commonly manufactured from copper based alloys due to its superior conductive properties. Electrodes are cooled by water flowing through cavities inside the electrode and the other conductive tooling of the resistance welding machine.

Hanson's resistance welding systems are designed and built for a wide range of industrial, automotive, and aerospace applications. Through automation, the action of these machines is highly controlled and repeatable allowing manufacturers to staff production readily.

About

Welding &

Automation, Inc.

PO Box 940

Flatrock, NC 28731

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: 1-828-674-1233

or 1-828-684-9709 x 22

Flatrock, NC 28731

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone: 1-828-674-1233

or 1-828-684-9709 x 22